Newsletter December 2025

December 1, 2025

Why Wood Scaffold Planks Are Still the Industry Standard

January 21, 2026

News & Updates

As we step into the New Year, we remain committed to what matters most—quality, safety, and reliability on every job site.

Thank you to the contractors, suppliers, and partners who trust Indian Mill Plank to support their projects year after year. We look forward to building stronger, safer job sites together in the year ahead.

🚧 Here’s to a year of solid footing and dependable performance.

Shield your scaffold planks with RHINO SKIN, a premium clear-drying sealant designed to protect against moisture, wear, and harsh job site conditions. Extend the life of your planks while maintaining strength and safety with every use.

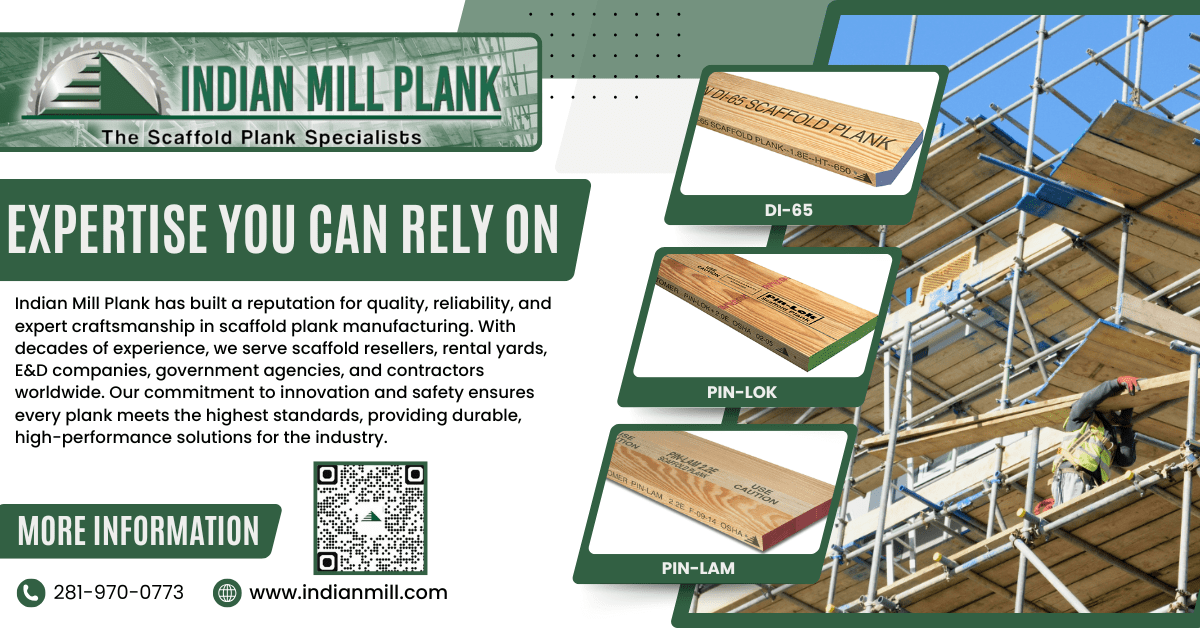

We have built a reputation for quality, reliability, and expert craftsmanship in scaffold plank manufacturing.

With decades of experience, we serve scaffold resellers, rental yards, E&D companies, government agencies, and contractors worldwide. Our commitment to innovation and safety ensures every plank meets the highest standards, providing durable, high-performance solutions for the industry. Start the 2026 Year strong with our manufactured scaffold Planks.

Not all wood scaffold planks are created equal. Certified, properly manufactured planks go through controlled processes that ensure strength, consistency, and reliability under real-world job-site conditions.

Certified scaffold planks offer:

- Verified load-bearing capacity

- Controlled moisture content to prevent cracking or swelling

- Structural grading to eliminate weak or defective boards

- Consistent dimensions for stable scaffold assembly

Using uncertified or low-grade planks may seem cost-effective upfront, but they significantly increase the risk of failure, accidents, and non-compliance with safety standards.

By choosing planks manufactured to strict quality and safety guidelines, contractors reduce risk, protect workers, and maintain uninterrupted project timelines.

Winter Jobs Require Reliable Materials.

Cold-weather conditions place added stress on scaffolding systems and job site materials. Indian Mill Plank scaffold planks are precision-manufactured for consistency and built to deliver dependable performance in demanding environments—even when temperatures drop, and conditions aren’t ideal.

Engineered for strength. Built for the job.

Our Products & Services

PIN-LOK

Indian Mill Plank proudly offers PIN-LOK 2.0E planks for unmatched strength and reliability. In our patented pinning process, the multiple structural components of select woods are milled to size, and screw-locking pins are inserted down the length of the plank. This makes PIN-LOK planks the most functional, durable, consistent, and longest-lasting wooden scaffold planks with an incredible strength-to-weight ratio.

DI-65

The solid-sawn scaffold plank has been the original scaffold plank or OSHA decking board of the industry for many years, and Indian Mill Plank has been producing them with the utmost quality. We are here to be your partner for the most reliable, safest scaffolding.

PIN-LAM

The PIN-LAM laminated scaffold planks are different in that individual pieces of solid-sawn lumber and LVL are locked together by twist-lock steel pins, creating an exceptionally strong, consistent, durable, and dependable working surface. With the LVL locked in the beam and header orientation between solid woods, the strength created in PIN-LAM is much greater than regular horizontal LVL scaffold planks. Also, the LVL in the vertical position provides a traction strip down the full length of the plank.

SPT-6

The SPT-6 streamlines the inspection process, ensuring your planks meet industry standards and are ready to support your team’s hard work. By incorporating this technology into your maintenance routine, you can extend the lifespan of your boards and reduce the risk of accidents on the job.

RHINO SKIN

Rhino Skin scaffold sealant adds tremendous protection and safety to scaffold worksites by helping to keep planking in OSHA-compliant condition and saving the contractor money by improving the longevity of their product.